- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

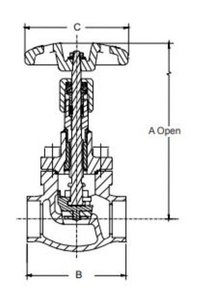

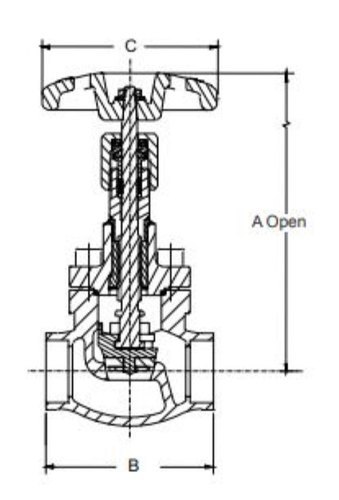

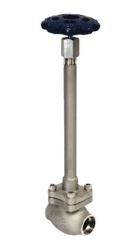

REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

275000.00 - 500000.00 INR/Piece

Product Details:

- Features Short stem design for low heat leak, anti-blowout stem, fire safe, easy maintenance

- Material Stainless Steel CF8M / 316

- Control System Manual (Handwheel)

- Valve Size Available in 1/2, 3/4, 1, 1-1/2, 2 sizes

- Valve Type Short Stem Globe Valve

- Connection Type Butt Weld, Socket Weld, or Female NPT

- Sealing PTFE / PCTFE (Polychlorotrifluoroethylene)

- Click to View more

X

REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem Price And Quantity

- 10 Unit

- 275000.00 - 500000.00 INR/Piece

REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem Product Specifications

- Up to 40 bar (580 psi)

- Short stem design for low heat leak, anti-blowout stem, fire safe, easy maintenance

- Stainless Steel CF8M / 316

- Manual (Handwheel)

- PTFE / PCTFE (Polychlorotrifluoroethylene)

- Cryogenic Globe Valve

- Globe Valve

- Varies: Typically 1/2 to 2

- Manual Operation

- Cryogenic Liquids: Oxygen, Nitrogen, Argon, Carbon Dioxide

- Available in 1/2, 3/4, 1, 1-1/2, 2 sizes

- Stainless SteelHardened and Polished for tight shut-off

- Designed for cryogenic service applications including liquid oxygen, nitrogen, argon, and carbon dioxide.

- Stainless Steel

- Short Stem Globe Valve

- -196C to +65C (-320F to +150F)

- Butt Weld, Socket Weld, or Female NPT

REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Model Name/Number | SKS Advantage Series |

| Brand | REGO |

| Body Material | Stainless Steel |

| Usage/Application | Cryogenic Liquids |

Application

The SKS Series globe valves short stem are designed for handling of cryogenic liquids through bulk tanks, trucks, trailers, ISO-containers and piping configurations. Our time tested spring-loaded stem packing and superior seat design provide for long life and easy maintenance.

Features

Superior Flow: Provides high Cv for rapid and reliable loading and unloading.

Designed with the unique Kold-Seal.

Conical PCTFE Seat: provides exceptional flow; bubble-tight seal; less chance of debris trapped in the seat and longer service life.

Connections: Socket Weld and Butt Weld.

Sizes: to 1.

Bonnet Type: Bolted.

Pressure Rating: 720 psig (50 barg)

Temperature Rating: -320F (-196C) to +150F (+65C).

Service: Liquefied and Vaporized Atmospheric Gases and LNG for Trailers, Bulk Tanks, ISO-Containers and Piping Configurations.

Cleaned for Oxygen service per CGA G-4.1.

MaterialsBody ........................................... Stainless Steel ASTM A351 CF8 Bonnet and Tube Stainless Steel ASTM A351 CF8/ASTM A479 type 304 Stem .......................................Stainless Steel ASTM A582 S30300 Spring .....................................Stainless Steel ASTM A313 S30200 Packing................................................ Live-loaded PTFE Packing

Gasket ............................................................PTFE 25% Glass Fill

Seat Disc .......................................................PCTFE ASTM D1430

Seat Retainer....................................................... Brass ASTM B16 Bonnet Screws .................................................ASTM B16 C36000 Handwheel......................................................... Painted Aluminum

Quality / Facility Features

Material traceability in accordance with BS EN 10204 3.1

CE Marking per European Pressure Equipment Directive

PED Certified

Precision Engineered for Cryogenic Safety

REGO SKS Advantage Series Globe Valves are meticulously designed for cryogenic environments, ensuring precise control and secure shut-off with Class VI leakage rating. The short stem construction reduces thermal bridging, which helps maintain insulation efficiency and preserves media integrity under extreme temperatures. With external gland packing adjustment and anti-blowout stems, operators benefit from dependable service in high-risk applications.

Customizable for Diverse Installations

Whether you're working with butt weld, socket weld, or female NPT connections, the valve offers flexible configuration options tailored to fit any cryogenic piping infrastructure. Standard sizes range from 1/2" to 2", with custom solutions available upon request. This adaptability extends to both new builds and retrofits, providing a streamlined installation process for varied project needs and compliance across global regions, including Germany.

Long-Term Value and Durability

Manufactured with polished CF8M/316 stainless steel and hardened disc, the SKS Advantage Series guarantees exceptional corrosion resistance and superior durability. Fire-safe construction and easy maintenance features translate to reduced downtime, enhanced operational safety, and minimal total cost of ownership for exporters, importers, service providers, and end users managing cryogenic media.

FAQ's of REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem:

Q: How does the short stem design benefit cryogenic applications in the SKS Advantage Series globe valve?

A: The short stem design reduces heat ingress through the valve, preserving the insulation integrity of cryogenic piping systems and improving energy efficiency. This feature is particularly vital for maintaining stable media temperatures in applications such as liquid oxygen, nitrogen, argon, and carbon dioxide.Q: What are the standard connection types and can they be customized for specific projects?

A: Standard end connection options include butt weld, socket weld, and female NPT, but they can be customized upon request to accommodate unique piping requirements or retrofit situations. This flexibility allows seamless integration into varied cryogenic systems.Q: When should the stem packing be adjusted and how is it accomplished?

A: Stem packing can be externally adjusted using the gland, helping maintain leak-tight performance over time. Adjustment is advised if there are signs of leakage or after extended service intervals, ensuring continued compliance with Class VI leakage standards.Q: Where is the flow direction marked on the SKS Advantage Series globe valve?

A: The flow direction is clearly indicated on the body of the valve, guaranteeing correct installation and optimal operation for unidirectional flow control within cryogenic liquid systems.Q: What is the process for maintaining or servicing these globe valves?

A: Maintenance is straightforward thanks to the external adjustable gland and user-friendly construction. Regular inspection for packing integrity and periodic cleaning of the polished surfaces ensure long-term reliability and performance in cryogenic conditions.Q: What are the benefits of using PTFE stem packing and PCTFE sealing in this valve?

A: PTFE stem packing and PCTFE sealing offer exceptional chemical resistance and low friction operation, minimizing leakage and wear. These materials enhance the valve's longevity and reliability when exposed to aggressive cryogenic media.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |