- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

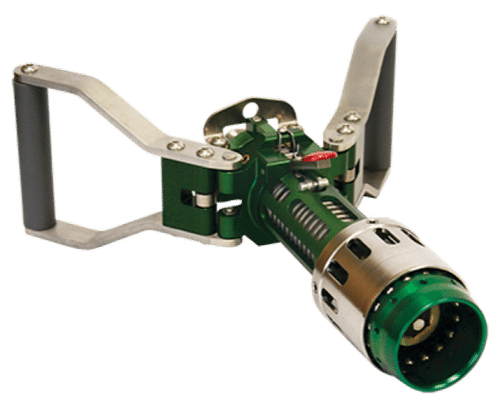

REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Size 1/2 inch to 2 inch

- Material 316L Stainless Steel

- Control System Manual Operation

- Features Rugged construction, Suitable for low temperature service, Easy Maintenance, Full Port Design

- Valve Type Cryogenic Globe Valve

- Connection Type Socket Weld, Butt Weld, Threaded

- Structure Globe

- Click to View more

X

REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

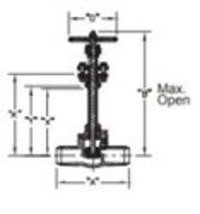

REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series Product Specifications

- Available from 1/2 to 2

- Cryogenic Service

- Globe Valve

- Manual Operation

- Manual

- Stainless Steel or PTFE

- Rugged construction, Suitable for low temperature service, Easy Maintenance, Full Port Design

- Stainless Steel

- Cryogenic Globe Valve

- PTFE or Metal to Metal

- Socket Weld, Butt Weld, Threaded

- Globe

- Up to 300 psig

- -196C to +60C

- 1/2 inch to 2 inch

- Liquefied Gases (LNG, LN2, O2, Ar, CO2 etc.)

- 316L Stainless Steel

REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Model Name/Number | 210 Series |

| Brand | REGO |

| Body Material | Stainless Steel |

Features Top Entry: This valve can be permanently installed in the line and serviced from the top

Soft Seated: PCTFE Seat provides a bubble-tight seal and is replaceable

Construction: Body and Bonnet ASTM A351 J92600 Stainless steel

Sizes: - 4 (15mm - 100mm)

Ends: RF Flange, Butt Weld, Socket Weld, Threaded (FNPT)

Service: Liquefied and vaporized atmospheric gases, LNG

100% Factory Tested

Clean for use in Oxygen per CGA G-4.1

Temperature Rating: -320F - 150F (-196C +65C)

Pressure Rating: (Cold, Non-shock) Class 150 valve - 275 psig (19 barg) Class 300 valve - 720 psig (50 barg)

- 4 Class 150 PED Approved

- 4 Class 300 PED Approved

Our investment cast stainless steel is specified by leading industrial gas companies for storage tank and yard operations. Special order bonnet extensions are available for cold box applications. Valves for hydrogen use can be supplied.

Precision Engineering for Cryogenic Applications

The 210 Series globe valve has been carefully designed to withstand extreme cryogenic temperatures. Key materials such as 316L stainless steel and PTFE packing contribute to reliability, while the extended bonnet prevents thermal transfer, making it highly effective for liquefied gas control in industrial, medical, and chemical environments.

Versatile Mounting and Connection Options

This valve accommodates various pipe configurations with socket weld, butt weld, and threaded (NPT/BSPT) end connections. Its flexible mounting orientation (vertical or horizontal) means it can be seamlessly integrated into existing systems, while the full bore structure allows maximum flow with minimal resistance.

Effortless Serviceability and Maintenance

Maintenance is straightforward-thanks to its in-line serviceable design, essential tasks such as replacing parts or sealing elements can be performed without valve removal. Spare parts availability further ensures longevity and cost-effective operation, keeping downtime to a minimum during routine checks.

FAQ's of REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series:

Q: How is the REGO 210 Series Globe Valve suitable for cryogenic applications?

A: The REGO 210 Series Globe Valve is expertly engineered with 316L stainless steel, low emission PTFE packing, and an extended bonnet to minimize thermal transfer, making it exceptionally well-suited for ultra-low temperatures down to -196C. Its bubble-tight sealing prevents leakage, essential for safely managing liquefied gases in cryogenic environments.Q: What are the installation options for this globe valve?

A: The valve offers versatile installation possibilities. It supports vertical or horizontal mounting positions and various end connections, including socket weld, butt weld, and both NPT or BSPT threaded types, making it easy to adapt to diverse piping systems in industrial or medical gas facilities.Q: When should the valve be serviced?

A: Routine servicing is recommended in accordance with system usage and operational demands. Because the valve is designed for in-line serviceability, you can maintain or replace components such as seals and packing without detaching the valve from the pipeline, minimizing downtime and facilitating quick maintenance cycles.Q: Where is this globe valve most effectively used?

A: Primary application areas include industrial gas distribution, medical gas systems, LNG distribution networks, and chemical processing facilities. Its construction is particularly advantageous in settings requiring reliable performance under cryogenic conditions and stringent leak prevention.Q: What is the process for maintaining this valve?

A: Maintenance involves shutting off the flow, relieving pressure from the system, and then servicing the valve in its installed position. Components like the handwheel, packing, or disc can be replaced onsite. The design simplifies internal inspections and seal upgrades, and spare parts are readily available from suppliers.Q: How does the design benefit system performance and longevity?

A: The full bore design reduces pressure drop, ensuring efficient media flow, while rugged stainless steel construction and advanced sealing systems provide a long service life, even in harsh cryogenic environments. This results in fewer replacements, lower maintenance costs, and consistently safe operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |