- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

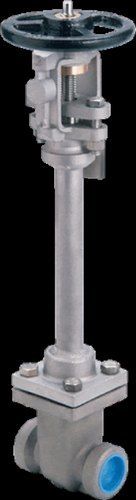

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

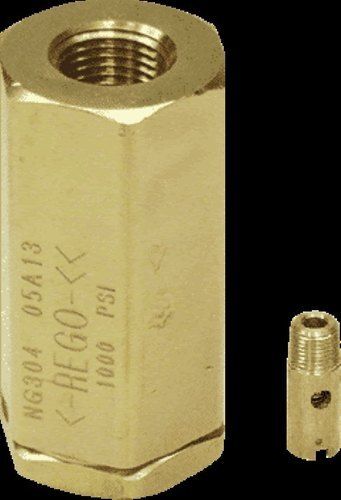

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

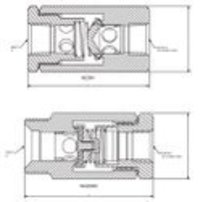

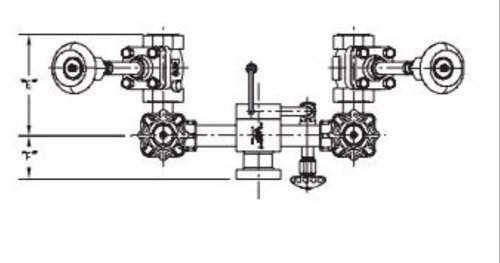

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

275000.00 - 500000.00 INR/Piece

Product Details:

- Material Bronze/Brass body with stainless steel trim

- Control System Manual Handwheel or Lever

- Valve Size 1/2 inch to 1 inch

- Connection Type NPT threaded

- Features High cycle life, leak-tight shutoff, easy maintenance, anti-blowout stem

- Valve Type Cryogenic Globe/Fill Manifold Valve

- Structure Robust manifold structure with multiple filling ports

- Click to View more

X

Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series Price And Quantity

- 10 Unit

- 275000.00 - 500000.00 INR/Piece

- Quarter turn or multi-turn handwheel

- Cylinder filling stations, bulk tank fills, cryogenic trailers, liquid transfer stations

- Optimized for high flow rates

- Panel and line mounting capability

- Non-rising, blow-out proof stem

- Bubble-tight, Class VI

- NPT female, customized connections available

- Low emission; non-adjustable or adjustable options

- Conform to CGA and ASME B31.3 standards

- CF Series, AFM Series, PFM Series, SFM Series

Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series Product Specifications

- Robust manifold structure with multiple filling ports

- Stainless steel guide or stem pin

- Bronze/Brass body with stainless steel trim

- Kel-F (PCTFE) or Stainless Steel

- Cryogenic liquid filling and transfer systems

- Liquid Oxygen, Nitrogen, Argon, Carbon Dioxide, LNG

- Fill Manifold Valve

- Manual/No external power required

- Max working pressure up to 600 psig (41 bar)

- NPT threaded

- 1/2 inch to 1 inch

- Manual Handwheel or Lever

- -196C to +65C (Cryogenic applications)

- 1/2 to 1 NPT

- PTFE, Kel-F (PCTFE), or Teflon seat and seals

- High cycle life, leak-tight shutoff, easy maintenance, anti-blowout stem

- Cryogenic Globe/Fill Manifold Valve

- Quarter turn or multi-turn handwheel

- Cylinder filling stations, bulk tank fills, cryogenic trailers, liquid transfer stations

- Optimized for high flow rates

- Panel and line mounting capability

- Non-rising, blow-out proof stem

- Bubble-tight, Class VI

- NPT female, customized connections available

- Low emission; non-adjustable or adjustable options

- Conform to CGA and ASME B31.3 standards

- CF Series, AFM Series, PFM Series, SFM Series

Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

ApplicationRegO Goddard high quality brazed and welded assemblies are ideally suited for the original equipment manufacturer of bulk cryogenic vessels. A wide variety of valve types including union or bolted bonnet, bronze or stainless steel bodies and top works and piping of stainless steel or copper construction are available as production unit.Ideal for all cryogenic liquids including Liquefied Nitrogen, Oxygen and Argon. Safe and reliably used in LNG Systems. In addition RegO can custom design configurations that are welded and brazed in a factory setting.

Features Unitized construction eliminates leaks and provides easy fit-up to tank piping

Modules commonly include top and bottom fill valves, fill check with strainer and hose bleed and relief valve

Many options are available which can include specific end user dimensions and specifications

Our valve products stand up to high cycle environments, without the need for field adjustment of valve packing

Available alone or as a unitized welded assembly for bulk tank filling

Repeatable performance and geometry

Precision silver brazed and welded assembly

Cleaned for Oxygen service per CGA G-4.1

Pressure Rating: 600 psig (41 barg)

Temperature Rating: -320F (-196C) to +165F (+74C)

100% Factory tested.

Materials

Globe Valve .............................................................Stainless Steel Check Valve.......................................................................... Brass Bleed Valve........................................................................... Brass Tube ............................................ 304L Stainless Steel or Copper

Versatile Cryogenic Filling Solutions

The Rego fill manifold series-including CF, AFM, PFM, and SFM-accommodates a wide range of cryogenic applications. Built with robust manifold structures and multiple filling ports, they provide reliable distribution and transfer for cylinder stations, liquid transfer points, and bulk storage systems. Their mounting flexibility enables integration into both panel and line setups, supporting diverse operational needs.

Superior Leakage Protection and Safety

These manifold valves are engineered for bubble-tight, Class VI leak protection, utilizing PTFE, Kel-F (PCTFE), or Teflon seals and seats for enhanced durability. The non-rising, blow-out proof stem and stainless steel guiding pins increase operational safety, while packing options (low emission, adjustable or non-adjustable) minimize possible leakage in demanding cryogenic conditions.

Compliant Design and Reliable Operation

All valves meet stringent CGA and ASME B31.3 standards, ensuring consistent performance and regulatory compliance. With manual quarter-turn or multi-turn handwheel operation, users benefit from easy control without external power requirements. The structure is optimized for high flows and supports pressure ratings up to 600 psig (41 bar), delivering effective performance in any cryogenic liquid filling or transfer application.

FAQ's of Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series:

Q: How do I choose the right Rego Cryogenic Fill Manifold series for my application?

A: Select the series-CF, AFM, PFM, SFM-based on your filling requirements, flow rate, port size, and operational setup (panel or line mounting). Each series is optimized for specific applications such as cylinder filling stations, bulk tank fills, or liquid transfer stations.Q: What types of cryogenic media can the Rego fill manifold valves handle?

A: These valves are suitable for a range of cryogenic liquids, including oxygen, nitrogen, argon, carbon dioxide, and LNG, thanks to their robust materials and specialized seals (PTFE, Kel-F, or Teflon).Q: When should routine maintenance be performed on the manifold valves?

A: Periodic inspections are recommended, especially in high-cycle or critical operations, to ensure leak-tight performance and safety. Easy maintenance features facilitate quick servicing, minimizing operational downtime.Q: Where are Rego Cryogenic Fill Manifold valves typically installed?

A: Common installation sites include cryogenic cylinder filling stations, bulk tank filling systems, cryogenic trailers, and liquid transfer stations. Their design supports both panel and line mounting for versatile placement.Q: What is the process for connecting the valves to my system?

A: Manifold valves come with NPT female threaded end connections, but customized connections are also available. Install according to your system's configuration, ensuring secure, leak-free joints for optimal performance.Q: How does manual operation benefit users?

A: Manual operation (quarter-turn or multi-turn handwheel) allows precise flow control without external power, increasing safety and reliability in hazardous or remote environments.Q: What are the primary benefits of using Rego's fill manifold valves for cryogenic liquid applications?

A: Key advantages include high cycle life, dependable leak-tight shutoff, user-friendly maintenance, robust safety features like anti-blowout stems, and compliance with industry standards, ensuring secure and efficient liquid transfer and filling operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |