- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

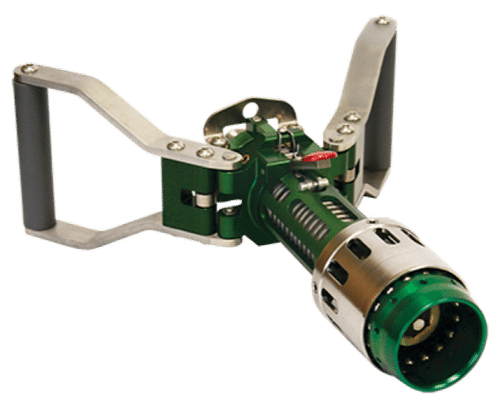

REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Type Cryogenic Gate Valve

- Valve Size DN15 (1/2) to DN300 (12)

- Control System Manual Handwheel Operation

- Material Stainless Steel (CF8M / CF8)

- Connection Type Flanged, Butt-Weld, Socket-Weld

- Features Blowout-proof stem, Locking device, Extended bonnet for cryogenic insulation, Low fugitive emission packing

- Structure Rising Stem, Bolted Bonnet

- Click to View more

X

REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series Product Specifications

- Stainless Steel

- Cryogenic Gate Valve

- DN15 (1/2) to DN300 (12)

- Manual

- Rising Stem, Bolted Bonnet

- Manual Handwheel Operation

- Class 150 to 800

- -196C to +80C

- PTFE / Metal to Metal

- Stainless Steel (CF8M / CF8)

- Full Bore

- Gate Valve

- Flanged, Butt-Weld, Socket-Weld

- Liquid & Gas

- Blowout-proof stem, Locking device, Extended bonnet for cryogenic insulation, Low fugitive emission packing

- Wedge Type (Solid or Flexible)

- Cryogenic Service (LNG, oxygen, nitrogen, argon, carbon dioxide & other cryogenic fluids)

REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Model Name/Number | 110 Series |

| Brand | REGO |

| Body Material | Stainless Steel |

ApplicationRegO Goddard gate valves are designed for handling of cryogenic liquids through bulk tanks, trucks, trailers, ASU plants and piping configurations. Compatible with Oxygen, Nitrogen, CO2, Argon and LNG.

Features

Top Entry: This valve can be permanently installed in the line and serviced from the top Soft Seated: PCTFE Seat provides a bubble-tight seal and is replaceable

Construction: Body and Bonnet ASTM A351-CF8 J92600 Stainless steel

Sizes: - 6 (15mm - 150mm)

Ends: RF Flange, Butt Weld, Socket Weld, Threaded (FNPT)

Service: Liquefied and vaporized atmospheric gases, LNG

WHZ valves with Grafoil stem packing available

Temperature Rating: -320F - 150F (-196C +65C)

100% Factory Tested

Clean for use in Oxygen per CGA G-4.1

PED Approved

Pressure Rating: (Cold, Non-shock) Class 150 valve - 275 psig (19 barg) Class 300 valve - 720 psig (50 barg)

Precision Engineering for Cryogenic Applications

The REGO 110 Series gate valve is thoughtfully designed with an extended bonnet to ensure insulation and integrity at temperatures ranging from -196C to +80C. Its polished finish enhances durability, while special stem packing (Graphite/PTFE) ensures low emission and reliable sealing even in demanding cryogenic services. These design attributes cater specifically to the needs of industries such as chemical, petrochemical, and industrial gas handling.

Versatile Connections and Robust Standards

Adaptable to various piping systems, this gate valve comes with end connections that meet ANSI, DIN, and JIS standards. The design fully conforms to recognized standards including ASME B16.34, API 600, and API 598, guaranteeing secure installation and dependable long-term performance. Available connection types include flanged, butt-weld, and socket-weld, making it suitable for broad industrial and commercial use.

Efficiency and Safety in Flow Control

Designed for unidirectional or bidirectional flow, the REGO 110 Series ensures tight shut-off and safety through its blowout-proof stem and flexible sealing mechanisms. The rising stem, outside screw & yoke (OS&Y), and bolted bonnet structure provide straightforward operation while facilitating maintenance. Locking device and manual handwheel control further enhance operational safety and reliability.

FAQ's of REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series:

Q: How does the extended bonnet design benefit cryogenic applications?

A: The extended bonnet design helps insulate the stem and packing area from extreme cold, preventing ice formation and maintaining the integrity of the seal. This ensures reliable operation and safety when handling cryogenic fluids at temperatures as low as -196C.Q: What standards and certifications does the REGO 110 Series Gate Valve comply with?

A: This valve is manufactured in accordance with ASME B16.34, API 600, and API 598 standards. It is also available with ANSI, DIN, and JIS end connection standards as per request, ensuring compatibility with various international systems and regulatory compliance.Q: When should I use this gate valve in my process system?

A: This gate valve is ideal for processes requiring tight shut-off and safe control of cryogenic fluids such as LNG, liquid nitrogen, oxygen, argon, and carbon dioxide. It is suitable for both industrial and commercial settings where reliable operation at low temperatures is essential.Q: Where can the REGO Stainless Steel Gate Valve be installed?

A: It can be installed in facilities that transport, store, or process cryogenic gases and liquids, including petrochemical plants, industrial gas suppliers, and cryogenic storage systems. The valve's connection options and adherence to major standards ensure seamless integration into various pipelines.Q: What is the process for ensuring a leak-free seal on this valve?

A: The valve undergoes rigorous body and seat testing-1.5 times and 1.1 times the rated working pressure, respectively-to confirm tight shutting and leak-free performance. Its PTFE or metal-to-metal sealing, combined with advanced stem packing, also helps achieve a reliable closure.Q: How do I operate and maintain the REGO 110 Series Gate Valve?

A: Operation is manual using the robust handwheel. Its outside screw & yoke (OS&Y) and rising stem make position indication and maintenance straightforward. Regular visual inspections and periodic lubrication of moving components ensure optimal performance over time.Q: What are the key benefits of choosing this cryogenic gate valve for my facility?

A: Key benefits include exceptional insulation performance at cryogenic temperatures, low emissions stem packing, bidirectional or unidirectional flow, secure manual control, and compliance with recognized industry standards. Features like the blowout-proof stem, full bore, and multiple size and connection options offer flexible and reliable operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |