- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

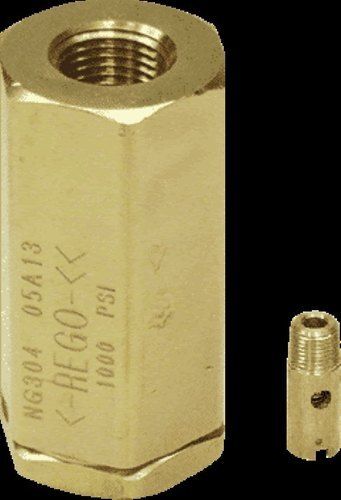

REGO Angle Relief Valve, ASME AR5100 Series

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Type Spring Loaded, ASME Section VIII Compliant

- Connection Type NPT Threaded

- Valve Size 1/2 Inch

- Control System Mechanical (Spring Operated)

- Features High flow capacity, Durable construction, Corrosion Resistance

- Material Body: Brass, Internal Parts: Stainless Steel

- Application LPG, NH3, Air, Other Gases and Liquids

- Click to View more

X

REGO Angle Relief Valve, ASME AR5100 Series Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

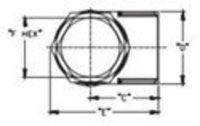

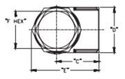

REGO Angle Relief Valve, ASME AR5100 Series Product Specifications

- Angle Relief Valve

- Body: Brass, Internal Parts: Stainless Steel

- Metal-to-Metal Seat

- High flow capacity, Durable construction, Corrosion Resistance

- 1/2 Inch

- Mechanical (Spring Operated)

- Set Pressure: 175 PSIG to 400 PSIG (12.1 barg to 27.6 barg)

- Angle Body

- Stainless Steel

- Brass or Stainless Steel

- 1/2 M NPT Inlet x 1/2 F NPT Outlet

- -20F to 150F (-29C to 65C)

- Spring Loaded, ASME Section VIII Compliant

- Gas/Liquid

- LPG, NH3, Air, Other Gases and Liquids

- NPT Threaded

- Manual

REGO Angle Relief Valve, ASME AR5100 Series Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Material | Brass/Bronze |

| Brand | REGO |

| Model Name/Number | AR5100 Series |

ApplicationThe ASME approved 90 relief valves AR Series, provide precise relief set-points which protect cryogenic vessels and piping systems for over-pressurization.

Features

High flow rates are approved by rigorous testing to ASME BVPC Code Section VIII

The 90 configuration provides relief of gases eliminating direct flow through the spring

The 90 configuration allows easy incorporation to plumbing for output containment

Bubble-tight seat provides 100% shut off when reseating or static mode

A variety of inlets and pressure settings assure adherence to application requirements

Temperature Range: -320F (-196C) to +165F (+74C)

Cleaned for Oxygen service per CGA G-4.1

100% Factory Tested

PED, TPED and ASME Certified

Materials

Body ............................................................. Bronze ASTM B61

Upper Body.................................... Stainless Steel ASTM A582

Seat and Stem................................................ Brass ASTM B16

Poppet Guide.................................................. Brass ASTM B16

Spring Retainer............................................... Brass ASTM B16 Adjusting Screw.............................................. Brass ASTM B16 Cap................................................................. Brass ASTM B16 Ball..................................................................... Stainless Steel Gasket .................................................. Copper ASTM B152-17 S

pring ............................................ Stainless Steel ASTM A313

Seal ..................................................................... Modified PTFE

Air Capacity= m x P

Where:

m = Slope Value

P= Pressure, Absolute @10% overpressure.

Example:

Pressure relief valve, inlet x 1 outlet, at 80 psig.

Part number AR5108A080.

m = 1.4

P= 80 psig

Air Capacity= 1.4 x [(80psig x 1.10) +14.7]

Air Capacity= 143.8 SCFM (air)

Flow Performance

AR5104A set pressures 75 - 500 capacity is 1.4 SCFM of air per psig of flow pressure.

AR5106A set pressures 75 - 400 capacity is 1.56 SCFM of air per psig of flow pressure.

AR5108A set pressures 75 - 425 capacity is 3.463 SCFM of air per psig of flow pressure.

AR5112A set pressures 80 - 425 capacity is 7.86 SCFM of air per psig of flow pressure. Flow pressure per ASME is 10% above set pressure or +3 psig, whichever is greater

Certifications

A - ASME, TPED, PED

B - ASME, TPED, PED

N - TPED, PED

Robust Construction for Demanding Applications

Engineered using high-quality brass with electroplating and stainless steel internal parts, the AR5100 Series Angle Relief Valve delivers exceptional durability and corrosion resistance. Designed for use with gases and liquids such as LPG, ammonia, and air, this valve ensures reliable operation even under challenging environmental and process conditions.

Precision Pressure Relief with Versatile Mounting

This spring-loaded angle relief valve is built with a vertical mounting orientation and a mechanical control system, providing accurate, dependable pressure release from 175 PSIG up to 400 PSIG. The vented discharge type and metal-to-metal seat construction make it ideal for fluid handling systems requiring robust overpressure protection.

Compliance and Optimal Performance

Fully compliant with ASME Section VIII, this 1/2-inch valve is suitable for critical safety applications. Its high flow capacity (Cv: 0.92) and manual operation support consistent response to overpressure events, making it a trusted component for industrial processes throughout India and beyond.

FAQ's of REGO Angle Relief Valve, ASME AR5100 Series:

Q: How is the REGO AR5100 Series Angle Relief Valve installed?

A: The valve is designed for vertical mounting and features a 1/2 M NPT inlet and 1/2 F NPT outlet thread. Simply connect it to the appropriate ports in your pressure system according to standard piping practices, ensuring proper alignment and secure sealing.Q: What types of media are suitable for use with this relief valve?

A: The AR5100 Series is constructed to handle a wide range of gases and liquids, including LPG, ammonia (NH3), air, and other compatible fluids. Ensure that your media is non-corrosive or suitable for contact with brass and stainless steel.Q: When should this relief valve be used in a system?

A: This valve is ideal for scenarios where pressure relief is critical, especially in LPG, ammonia, and compressed air systems. It is designed for use when set pressures between 175 PSIG and 400 PSIG are required to protect system integrity.Q: Where can the AR5100 Series valve typically be applied?

A: Typical applications include industrial storage tanks, process equipment, and pipeline systems that require overpressure protection. Its robust construction suits indoor and outdoor installations across diverse industries including chemical, energy, and gas distribution.Q: What is the process for setting the relief pressure of this valve?

A: Set pressure is factory calibrated between 175 and 400 PSIG as specified by the application. If a different set pressure is needed, consult the manufacturer or an authorized service provider for precise adjustment following industry standards.Q: How does the valve ensure safety and reliability?

A: The valve's spring-loaded, angle-body design offers quick, reliable response to overpressure events. Metal-to-metal seat sealing provides leak-tight shutoff, while the vented discharge helps safely direct relived media away from operators and equipment.Q: What are the benefits of using an AR5100 Series valve in your system?

A: Key advantages include high flow capacity (Cv: 0.92), mechanical spring operation for simple maintenance, and compliance with ASME Section VIII, ensuring regulatory adherence and peace of mind for overpressure protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |