- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

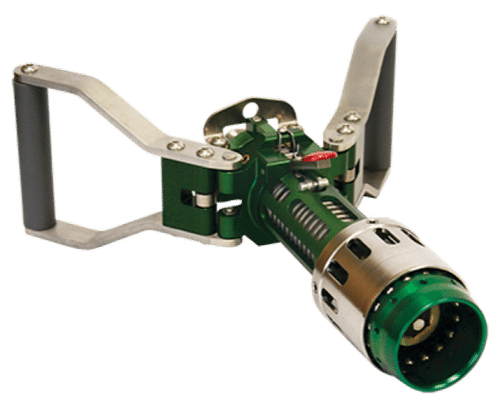

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

Rego LNG Male Fueling Receptacle MFR50 Series

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Type Check Valve

- Valve Size Fits standard MFR50 Series couplers

- Connection Type Threaded, 1/2 inch NPT

- Material Stainless Steel (316L)

- Control System Mechanical interlock

- Features Push-to-connect locking mechanism, low-loss design, corrosion resistant

- Structure Robust stainless steel body with integral locking design

- Click to View more

X

Rego LNG Male Fueling Receptacle MFR50 Series Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

Rego LNG Male Fueling Receptacle MFR50 Series Product Specifications

- Rated up to 362 psi (25 bar)

- Double O-ring seals

- Quick connect/disconnect male receptacle

- Push-to-connect locking mechanism, low-loss design, corrosion resistant

- 4-pin connection

- Manual operation, no power required

- Threaded, 1/2 inch NPT

- Fits standard MFR50 Series couplers

- Stainless Steel (316L)

- Liquefied Natural Gas (LNG)

- Stainless steel disc

- Mechanical interlock

- Check Valve

- 1/2 inch NPT

- Robust stainless steel body with integral locking design

- -40C to +85C

- Used in LNG vehicle fueling connections

Rego LNG Male Fueling Receptacle MFR50 Series Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

ApplicationWhen mounted on the tank of a Liquid Natural Gas fueled vehicle, the LNG Tank Receptacle offers a safe and secure connection with the CryoMac3 50M LNG Nozzle. In addition to providing a perfect fit with the CryoMac3 50M LNG Nozzle, the LNG Tank Receptacle is engineered to offer the same safe and secure connection with many other LNG Nozzles.

Features Max internal pressure 300 psig /20.7 barg (while fueling)

Max system pressure 550 psig /38 barg (static)

Flow capacity 50 GPM

Available in the more standard inlet connections

Temperature range -350F to 150F ( -212C to 65C)

100% pressure tested

Global certifications

66% lower LNG emissions during disconnect

Easy service

Different outlet available upon request

Robust poppet design and protection of seat for longer life

Patent pending

Materials

Body .....................................................316L Cres Per ASTM A312

Poppet ..................................................................303 ASTM A 582

Spring ........................................................... 302 Cres ASTM A313

Seal ASSY (C version) ............................................ UHMWL Brass

Seal ASSY (Non-C Version) ........................ Duronl Stainless Steel Retainer..................................................................................Brass Retainer ring............................................................Stainless Steel

Safety and Reliability

Rego's MFR50 Series receptacle offers enhanced safety through a double lock manual safety feature and mechanical interlock, preventing accidental disconnection during operation. Its leak rate is less than 0.01 cc/sec at maximum pressure, ensuring a secure and reliable LNG fueling process for vehicle applications.

Outstanding Durability

Constructed from electro-polished 316L stainless steel, the MFR50 Series is resistant to both cryogenic temperatures as low as -40C and harsh chemical environments. The design supports rigorous, high-frequency operation while maintaining corrosion resistance and mechanical strength.

Ease of Maintenance

The serviceable design allows for quick and straightforward replacement of O-rings and other wear parts. Maintenance can be performed without specialized equipment, reducing downtime and optimizing operational efficiency for fuel system managers.

FAQ's of Rego LNG Male Fueling Receptacle MFR50 Series:

Q: How does the Rego MFR50 Series ensure leak-free LNG fueling connections?

A: The MFR50 Series features high-integrity double O-ring seals, an integrated check valve, and precise machining to achieve a leakage rate below 0.01 cc/sec at maximum pressure, ensuring exceptional sealing performance during LNG transfer.Q: What makes the MFR50 Series compatible with harsh environments and cryogenic temperatures?

A: This receptacle is built with 316L stainless steel, is electro-polished for surface protection, and engineered to operate reliably in temperatures ranging from -40C to +85C, making it ideal for demanding chemical and cryogenic LNG applications.Q: When is maintenance required, and how is it performed on the MFR50 Series?

A: Maintenance is recommended as part of regular operational checks or when wear on O-rings is detected. The unit's serviceable design allows for the easy replacement of O-rings and other service parts without specialized tools, promoting quick, on-site maintenance.Q: Where can the MFR50 Series receptacle be installed?

A: The MFR50 Series is designed for installation in LNG vehicle fueling stations or LNG transfer systems, using its standard 1/2" NPT male threaded end. It is suitable for applications across a variety of regions, including Germany and global LNG fueling markets.Q: What is the process for connecting and disconnecting the MFR50 Series?

A: Connecting is achieved through a push-to-connect locking mechanism, while disconnection is secured by a manual double lock feature, ensuring simple yet safe operation without the need for external power sources.Q: What are the key benefits of using the Rego MFR50 Series for LNG vehicle fueling?

A: Benefits include rapid fueling with a flow rate up to 50 liters per minute, superior leak protection, resistance to harsh chemicals and temperatures, easy maintenance, and compliance with SAE J2044 standards-making it highly reliable for commercial LNG vehicle fueling.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |