- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

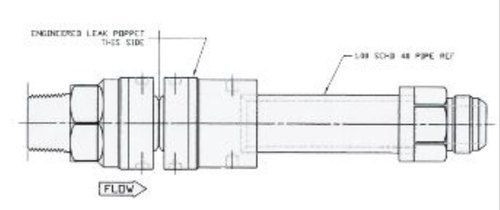

Rego LNG Vent / Fill Breakaway VFL Series

275000.00 - 500000.00 INR/Piece

Product Details:

- Material Brass, stainless steel, and aluminum

- Valve Type Automatic shutoff breakaway coupling

- Valve Size 1-1/4 inch

- Features Immediate shutoff upon disconnect, EMI integration, reusable after activation

- Connection Type Threaded (NPT)

- Control System Manual operation, automatic shutoff upon separation

- Application LNG transfer, venting, and filling operations

- Click to View more

X

Rego LNG Vent / Fill Breakaway VFL Series Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

- 3.2 kg (approx.)

- 10,000 cycles

- EN 13769, PED, and TPED approved

- ASME B31.3 compliant

- 250 lbs (typical)

- Field serviceable design

- Up to 350 GPM

- Breaks away cleanly under excessive force, preventing spillage

- Bubble-tight shutoff

Rego LNG Vent / Fill Breakaway VFL Series Product Specifications

- Brass, stainless steel, and aluminum

- Automatic shutoff breakaway coupling

- 1-1/4 NPT

- -196C to +65C

- Nickel plated brass or stainless steel

- Immediate shutoff upon disconnect, EMI integration, reusable after activation

- 1-1/4 inch

- Manual

- Breakaway fitting

- Manual operation, automatic shutoff upon separation

- Threaded (NPT)

- LNG transfer, venting, and filling operations

- Elastomeric seals

- Liquefied Natural Gas (LNG)

- Quick-connect breakaway coupling

- Max working pressure: 25 bar (362 psi)

- 3.2 kg (approx.)

- 10,000 cycles

- EN 13769, PED, and TPED approved

- ASME B31.3 compliant

- 250 lbs (typical)

- Field serviceable design

- Up to 350 GPM

- Breaks away cleanly under excessive force, preventing spillage

- Bubble-tight shutoff

Rego LNG Vent / Fill Breakaway VFL Series Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

ApplicationThe VFL Series are LNG vent/fill breakaway are designed to prevent pull away accidents, protect fill station/dispenser and eliminate unwanted product release.

Features

Max internal pressure 300 psig/20.7 barg (while fueling)

Max system pressure 550 psig/38 barg (static)

Temperature range -340F to 140F ( -206C to 60C).

Fill Breakaway Flow Capacity 50 GPM

Vent Breakaway Flow Capacity 10 GPM

100% pressure tested

Materials

Housing .................................... 304 Stainless Steel ASME SA479 Housing ............................................................... Brass ASTM B16 Poppet ................................................................. Brass ASTM B16 Spring ...............................................................302 Stainless Steel Guide................................................................... Brass ASTM B16 Hose Adapter............................ 304 Stainless Steel ASME SA479

Unmatched Safety and Performance

Rego VFL Series breakaway fittings deliver immediate shutoff upon unintentional separation, ensuring no LNG spillage. Designed with elastomeric seals and bubble-tight closure, their construction guarantees safe and reliable operation during LNG transfer, venting, and filling processes. Its quick-connect mechanism and robust materials withstand extreme conditions.

Designed for Longevity and Compliance

Built for durability, the breakaway fitting exceeds 10,000 operational cycles. Each unit is tested and fully compliant with international standards, such as ASME B31.3, EN 13769, PED, and TPED. This assures top-tier reliability and safety for distributors, exporters, importers, and service providers handling LNG in India.

FAQs of Rego LNG Vent / Fill Breakaway VFL Series:

Q: How does the Rego VFL Series breakaway fitting enhance safety during LNG operations?

A: The Rego VFL Series is engineered to break away cleanly under excessive force, immediately shutting off LNG flow and preventing hazardous spills. Its bubble-tight shutoff and quick-connect design protect personnel and equipment during accidental separation.Q: What is the typical process for installing and operating the VFL Series in LNG applications?

A: Installation involves connecting the threaded (1-1/4 NPT) coupling to LNG transfer lines. Operation is manualrequiring physical connection/disconnectionwhile the devices automatic shutoff activates during a breakaway event, sealing both ends instantly.Q: When should the VFL Series be serviced or maintained?

A: The VFL Series is field serviceable and should be inspected periodically in line with user protocols or after a breakaway incident. Routine maintenance ensures the coupling remains reliable for its 10,000-cycle service life.Q: Where can the Rego VFL Series be applied in the LNG transfer process?

A: This breakaway fitting is suitable for transfer, venting, and filling operations involving LNG, and is commonly used at terminals, fueling stations, and industrial facilities across India where secure and compliant LNG handling is essential.Q: What are the benefits of choosing a PED, TPED, and ASME B31.3 compliant breakaway coupling?

A: Selecting a compliant breakaway fitting like the Rego VFL Series ensures adherence to stringent safety and quality standards. It provides peace of mind regarding the integrity of LNG operations and can support regulatory approvals for diverse applications.Q: How does the reusable design of the VFL Series improve operational efficiency?

A: After activation due to excessive force, the VFL Series coupling can be reset and reused, unlike single-use alternatives. This feature minimizes downtime and replacement costs, enhancing operational continuity for LNG suppliers and end-users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |