- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

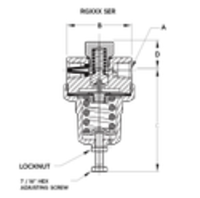

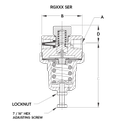

REGO RG Series Cryogenic Pressure Builder or Regulator

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Type Pressure Builder / Regulator

- Valve Size 1/2 inch

- Connection Type NPT Female

- Features High flow capacity, compact design, excellent pressure control, low temperature compatibility

- Material Brass body, Stainless Steel trim

- Control System Spring-loaded, self-operated

- Sealing PTFE/Neoprene

- Click to View more

X

REGO RG Series Cryogenic Pressure Builder or Regulator Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

REGO RG Series Cryogenic Pressure Builder or Regulator Product Specifications

- Manual

- Cryogenic fluids: LIN, LOX, LAR, LCO2, LNG

- 1/2 inch

- Single inlet and outlet port

- 1/2 NPT

- Pressure Builder / Regulator

- NPT Female

- -196C to +74C (-320F to +165F)

- Stainless Steel / PTFE

- Cryogenic Pressure Regulator

- PTFE/Neoprene

- Brass body, Stainless Steel trim

- Spring-loaded, self-operated

- Pressure builder/regulator

- Cryogenic gas pressure building and regulation

- High flow capacity, compact design, excellent pressure control, low temperature compatibility

- Set pressure range: 40 to 550 psig (2.8 to 37.9 bar)

REGO RG Series Cryogenic Pressure Builder or Regulator Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Brand | REGO |

| Model Name/Number | Cryogenic Pressure Builder RG Series |

| Material | Brass/Bronze |

| Media | Liquid |

| Valve Size | 1/4", 3/8, 1/4" |

Application

RG series cryogenic regulators are primarily designed to maintain pressure on cryogenic liquid within cryogenic containers. They may also be used in cryogenic lines, vaporizer and converter applications. They are especially useful in installations where space and cost limitations are important.

Features- All parts are copper alloy (brass), PTFE and stainless steel materials selected specifically for compatibility with cryogenic temperatures down to -320 F. (-196 C )

- PTFE seat helps assure a positive shut-off at cryogenic temperatures down to -320 F. (-196 C )

- High and low pressure regulators are the same compact size designed to fit in close quarters.

- Interchangeable with existing cryogenic regulator units.

- Inlet filter helps prevent foreign material from entering the regulator.

- Locknut is provided to maintain adjusting screw setting.

- RG125C and RG175C Series available with flat inlet screen.

- RG000090AG is available with T handle adjustment screw and gauge ports.

- Maximum inlet pressure of 550 psig. (37.9 barg)

- Cleaned for oxygen service per CGA G-4.1

- 100% Factory Tested

- Body Brass

- Bonnet Brass

- Seat PCTFE

- Diaphragm Gasket PTFE

- Backcap Gasket Copper

- Springs Stainless Steel

- Diaphragm Bronze

Ordering Information

| Part Number | Inlet / Outlet Connections (F.NPT) A | Width B | C | D | Operating Range (psig) |

|---|---|---|---|---|---|

| RG022A | 2 1/16 | 3 | 1 | 0-30 psig (0-2.1 barg) | |

| RG125A | 25-250 psig (1.7-17.2 barg) | ||||

| RG125C3 | ??? | 2 1/8 | 3.33 | 0.80 | |

| RG175C3 | |||||

| RG300A | 2 1/16 | 3 | 1 | 125-350 psig (17.2-24.2 barg) | |

| RG000090AG |

|

|

|---|

High-Precision Pressure Control

The REGO RG Series regulator offers reliable and accurate pressure management, making it suitable for demanding cryogenic environments. Its wide range of outlet pressures allows customization according to specific system requirements, ensuring optimal operation for tanks, vaporizers, and micro-bulk storage.

Compliance and Quality Assurance

Every RG Series Pressure Builder is engineered in adherence to rigorous CGA and ASME standards. This commitment to compliance guarantees safety, durability, and consistent performance, making it a trusted solution for businesses in the cryogenic industry.

Ease of Maintenance and Installation

With its field-serviceable design and in-line mounting configuration, the RG Series simplifies both installation and upkeep. Custom factory settings further enhance convenience, so users can deploy the regulator with minimal adjustments.

FAQs of REGO RG Series Cryogenic Pressure Builder or Regulator:

Q: How is the REGO RG Series Cryogenic Pressure Builder or Regulator installed?

A: The regulator is designed for in-line mounting, facilitating easy integration into existing cryogenic tank, vaporizer, or micro-bulk storage systems. Installation procedures should follow manufacturer guidelines and safety standards.Q: What pressure ranges are available for the RG Series regulator?

A: The RG Series offers three outlet pressure variants: 40200 psig, 100350 psig, and 300550 psig. This flexibility allows users to select the most suitable range for their application requirements.Q: When should I consider custom factory pressure settings?

A: Custom factory settings are recommended when your application requires precise pressure control outside the standard factory presets. You can request tailored settings during the ordering process to ensure optimal performance.Q: Where can the RG Series regulator be used in cryogenic setups?

A: It is typically implemented in cryogenic tanks, vaporizer systems, and micro-bulk storage setups. Its usage is prevalent in industries needing stringent pressure management for handling cryogenic liquids.Q: How does the Cv value of 0.75 benefit system performance?

A: A Flow Coefficient (Cv) of 0.75 ensures efficient flow rates, minimizing pressure drops while maintaining precise control. This contributes to reliable, energy-efficient operation in cryogenic applications.Q: What maintenance process is required for the RG Series regulator?

A: Thanks to its field-serviceable design, routine maintenance can be conducted on-site using standard tools. This reduces downtime and service costs, ensuring prolonged product life and consistent performance.Q: What advantages does compliance to CGA and ASME standards offer?

A: Adherence to CGA and ASME standards assures high safety, quality, and industry acceptance. Using compliant equipment enhances confidence in system reliability and regulatory assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cryogenic Valves' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |