- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

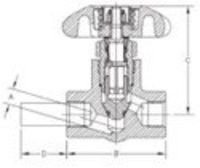

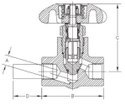

Short Stem Cryogenic Valves

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Size 1/2 Inch to 6 Inch

- Control System Manual or Actuator Ready

- Features Low Emission, Anti-static device, Blow-out proof stem, Fire Safe Design, Extended Bonnet option

- Material Stainless Steel, CF8, CF8M, Forged Steel

- Valve Type Ball, Gate, Globe, Check Valve

- Connection Type Screwed, Flanged, Butt Weld Ends

- Sealing PTFE or Metal Seated

- Click to View more

X

Short Stem Cryogenic Valves Price And Quantity

- 10 Unit

- 275000.00 - 500000.00 INR/Piece

Short Stem Cryogenic Valves Product Specifications

- 1/2 Inch to 6 Inch

- Stainless Steel

- Manual or Actuator Ready

- 1/2 Inch to 6 Inch

- Stainless Steel, CF8, CF8M, Forged Steel

- -196C to +80C

- Gas, Liquid

- Low Emission, Anti-static device, Blow-out proof stem, Fire Safe Design, Extended Bonnet option

- Ball, Gate, Globe, Check Valve

- Up to Class 150/300/600

- PTFE or Metal Seated

- Short Stem Cryogenic Valve

- For cryogenic service, suitable for LNG, nitrogen, oxygen, argon, and other liquefied gases handling.

- Bolted Bonnet

- Manual

- Screwed, Flanged, Butt Weld Ends

Short Stem Cryogenic Valves Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Material | Brass |

| Brand | REGO |

| Usage/Application | Cryogenic/LNG Fueling |

| Model Name/Number | T9450-9460 |

Application

The T9450 and T9460 series valves are designed for use on portable cryogenic cylinders and other in-line shut-off valve applications. T9460 Series Approved for TPED in accordance with EN1626.

Features- Spring loaded stem seal automatically adjusts for any gasket wear, eliminating the need to constantly retighten the packing nut.

- Non-rising stem and low profile allow the valve to fit into tight areas and still provide easy access.

- Unique pressure-sealed moisture barrier helps prevent freeze up at cryogenic temperatures.

- Conical swivel seal design helps prevent seat galling from over torquing.

- Cleaned for oxygen service per CGA G-4.1.

- Maximum working pressure is 600 psig. (42 barg)

- Working temperature range is -320F to +165F. (-196C to +74C)

- 100% Factory Tested

- BodyBrass

- BonnetBrass

- Seat DiscPCTFE

- Stem Seal GasketPTFE

- HandwheelAluminum

- SpringStainless Steel

- StemBrass

- PoppetBrass

Comprehensive Cryogenic Compatibility

Our Short Stem Cryogenic Valves are built to handle extremely low temperatures from -196C up to +80C, making them ideal for critical cryogenic services such as LNG, industrial gases, and laboratory applications. With reliable sealing-PTFE or metal-seated-and robust stem packing, these valves ensure consistent leak-tight performance under thermal cycling and demanding conditions.

Certified Quality and Flexible Design

Each valve adheres strictly to international standards including ASME B16.34, BS 6364, and API 6D. Extensive testing as per BS 6364 Cryogenic Tests and API 598/EN 12266 guarantees operational safety. Customizable bonnet extension lengths, multiple surface finishes, and broad end connection options make integration seamless for diverse systems and specifications.

FAQ's of Short Stem Cryogenic Valves:

Q: How are Short Stem Cryogenic Valves used in cryogenic service applications?

A: Short Stem Cryogenic Valves are specifically designed for controlling the flow of liquefied gases such as LNG, nitrogen, oxygen, and argon in environments where temperatures may reach as low as -196C. Their robust construction and extended bonnet ensure insulation and reliable sealing in these conditions.Q: What benefits do CF8, CF8M, and Forged Steel materials provide for these valves?

A: CF8, CF8M, and Forged Steel offer outstanding mechanical strength and corrosion resistance, which are critical for maintaining valve integrity and longevity in aggressive cryogenic and industrial environments.Q: When should you choose PTFE or graphite stem packing for these valves?

A: PTFE packing is recommended for applications requiring chemical resistance and low friction, whereas graphite packing is preferred for high-temperature applications due to its superior thermal stability and sealing performance.Q: Where can these valves be installed and what connection types are available?

A: These cryogenic valves are suitable for installation in industrial plants, LNG terminals, and gas handling facilities. They are available with flanged, screwed, or butt-weld end connections, ensuring compatibility with a wide range of pipeline systems.Q: What is the typical process for testing these short stem cryogenic valves?

A: Testing follows BS 6364 Cryogenic Test and API 598/EN 12266 standards, which involve stringent leak testing at ambient and cryogenic conditions, ensuring leak-tight and reliable performance under actual service conditions.Q: How does the fire-safe design benefit operational safety?

A: The valves are certified to meet API 607 fire-safe standards, meaning they maintain their sealing performance even in the event of a fire, preventing hazardous leakage and enhancing overall plant safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cryogenic Valves' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |