- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

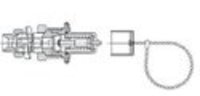

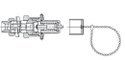

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

Rego MQD100 Series Cryogenic Valve

275000.00 - 500000.00 INR/Piece

Product Details:

- Valve Type Manual Globe Valve

- Material Bronze or Brass Body, Stainless Steel Trim

- Valve Size 1/4 to 1-1/2 NPT

- Features Bubble-tight shutoff, Non-rising stem, Extended bonnet for insulation, Serviceable packing

- Control System Manual Handwheel

- Connection Type Threaded (NPT)

- Structure Globe Valve

- Click to View more

X

Rego MQD100 Series Cryogenic Valve Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 , , Unit

Rego MQD100 Series Cryogenic Valve Product Specifications

- 1/4 to 1-1/2 (6mm to 38mm)

- Cryogenic Globe Valve

- Globe Valve

- Max Working Pressure: 600 psig (41.4 bar)

- Bronze or Brass Body, Stainless Steel Trim

- Stainless Steel with PTFE Insert

- Cryogenic Liquids, Gases

- 1/4 to 1-1/2 NPT

- Bubble-tight shutoff, Non-rising stem, Extended bonnet for insulation, Serviceable packing

- Manual Globe Valve

- Manual Operation

- PTFE/Soft Seat

- Cryogenic liquid service, LNG, Liquid Oxygen, Nitrogen, Argon, Carbon Dioxide

- Threaded (NPT)

- Manual Handwheel

- -320F to +165F (-196C to +74C)

Rego MQD100 Series Cryogenic Valve Trade Information

- 100 , , Unit Per Week

- 1 Week

Product Description

| Material | Stainless Steel |

| Brand | REGO |

| Usage/Application | LNG Vehicle Tank |

| Model Name/Number | MQD100 Series |

Application

For venting excess pressure in LNG vehicle tanks.

Engineered for easy connection / disconnection with quick disconnect vent couplers.

Features

Designed for durability and long lasting performance

Materials selected specifically for compatibility with LNG

PTFE seat provides positive shut off at cryogenic temperatures

Temperature range: -325F(-198C) to +150F(+65C)

100% factory tested

Max fueling pressure: 300 psig (20.7 barg)

Max system pressure: 550 psig (38 barg)

Designed in accordance with & approved by ECE R110

Materials

Inlet body....................................................................Stainless Steel Body ..........................................................................Stainless Steel Seat .........................................................................................PTFE Spring ........................................................................Stainless Steel Cap (optional).............................................................................Viny

Superior Cryogenic Insulation

Featuring an extended bonnet, the MQD100 Series is meticulously engineered to minimize thermal loss and ice formation, ensuring optimal insulation during cryogenic service. This design maintains the integrity of media at extremely low temperatures, preserving efficiency and safety in critical liquid and gas flow applications.

Reliable and Durable Construction

Built with a nickel-plated bronze or brass body and stainless steel trim, the valve offers exceptional corrosion resistance and longevity. The adjustable PTFE V-ring packing and soft PTFE seat enhance its sealing performance, providing a bubble-tight shutoff and consistent reliability throughout its extended service life.

Flexible Installation and Usage

The valve's non-rising stem and manual, aluminum handwheel control allow smooth operation in any mounting position. Threaded NPT connections, with optional BSPP, ensure compatibility with varied pipeline systems, making it ideal for distributors, manufacturers, and suppliers involved in cryogenic processes.

FAQ's of Rego MQD100 Series Cryogenic Valve:

Q: How does the extended bonnet design benefit cryogenic applications?

A: The extended bonnet insulates the stem and packing area, significantly reducing heat ingress. This minimizes the risk of ice forming and maintains the integrity of cryogenic liquids and gases during operation, enhancing safety and valve performance in ultra-low temperature environments.Q: What is the maximum working pressure and temperature range for the MQD100 Series valve?

A: The valve is designed to handle up to 600 psig (41.4 bar) and can operate within a temperature range from -320F to +165F (-196C to +74C), making it suitable for a broad spectrum of cryogenic media.Q: When should the adjustable PTFE V-ring packing be serviced or maintained?

A: The adjustable PTFE V-ring packing should be inspected periodically for signs of wear or leakage, especially after extended use in demanding cryogenic conditions. Regular maintenance ensures consistent bubble-tight sealing and prolongs the valve's lifespan.Q: Where can the Rego MQD100 Series cryogenic valve be installed?

A: Thanks to its versatile design, the valve can be mounted in any position. Its threaded NPT end connections accommodate various piping layouts, making it suitable for installation in industrial cryogenic storage, transport systems, and processing plants.Q: What process is required to change from NPT to BSPP end connections?

A: To obtain BSPP end connections instead of standard NPT threads, indicate this requirement during ordering with your supplier. The manufacturer then provides the valve with BSPP threading, ensuring seamless integration into British Standard piping systems.Q: How is manual operation achieved and what are the advantages?

A: Manual operation is facilitated by the robust aluminum handwheel, allowing precise control over flow. Manual actuation ensures simple, reliable valve performance even in environments where automated systems might be prohibitive, such as remote or hazardous settings.Q: What benefits does nickel-plating provide to the valve body?

A: Nickel-plating greatly enhances the valve's resistance to corrosion, especially important in cryogenic and wet environments. This finish extends the valve's usable life and maintains its performance even after prolonged exposure to cold media and challenging conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cryogenic Valves' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |