- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

ECL502 Series Cryogenic Economizer

275000.00 - 500000.00 INR/Piece

Product Details:

- Material Stainless Steel 304/316L

- Valve Size 1/2 to 2

- Connection Type Butt Weld, Socket Weld, Screwed Ends

- Features Low Temperature Operating, Anti-corrosive, High Flow Efficiency

- Valve Type Cryogenic Economizer Valve

- Control System External Pilot Pneumatic Operator

- Voltage 24V DC / 220V AC

- Click to View more

X

ECL502 Series Cryogenic Economizer Price And Quantity

- 275000.00 - 500000.00 INR/Piece

- 10 Unit

ECL502 Series Cryogenic Economizer Product Specifications

- Stainless Steel 304/316L

- 1/2 to 2

- Cryogenic Liquids and Gases

- PTFE / Metal to Metal

- Pilot Operated

- Butt Weld, Socket Weld, Screwed Ends

- 2-pin

- External Pilot Pneumatic Operator

- Up to 40 bar

- Cryogenic Economizer Valve

- Low Temperature Operating, Anti-corrosive, High Flow Efficiency

- DN15-DN50

- Stainless Steel

- 24V DC / 220V AC

- Pneumatic

- Economizer Valve

- Cryogenic Gas Systems, Pressure Control, LNG, Air Separation Plants

- -196C to +80C

ECL502 Series Cryogenic Economizer Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

Application

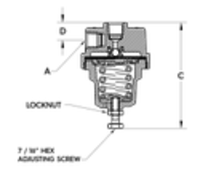

ECL502 series cryogenic economizers are designed to be used as pressure reducing valves to automatically maintain a constant inlet or back pressure, normally closed at pressures below its set point and open at pressures above its set point. The ECL502 is primarily designed to assist in maintaining a desired system pressure ideal for Nitrogen, Oxygen, Argon and other cryogenic cylinder applications with a 100% performance improvement over RegOs ECLXXX series. ECL502 series offers outstanding performance for maintaining LNG fuel line pressure.

Features

ECL502 series design provides premium flow characteristics allowing for fast pressure reduction while maintaining sensitive flow control at lower pressure settings.

All materials of construction- copper alloy, PTFE and stainless steel were selected for compatibility with cryogenic service.

150 count mesh Monel screens installed into the inlet and outlet ports prevent debris from entering or damaging any downstream components.

Interchangeable with existing cryogenic economizer units.

Bi-directional flow for LNG fuel systems

Temperature range: -320F to +165F (-196C to +74C)

Max inlet pressure: Low Pressure Models 175: 375 psig ( 12,1: 25.3 barg), High Pressure Models >175: 550 psig (> 12,1: 37.9 barg)

Pressure setting range: 10-350 psig (0.7-24.1 barg)

Clean for oxygen service per CGA G-4.1

Design in accordance with ECE R110

Materials

Body Brass

Diaphragm Liner PTFE

Poppet Seat Stainless Steel

Adjusting Screw Stainless Steel

Bonnet Brass

Screen Monel

Diaphragm Bronze

Springs Stainless Steel

Ordering Information

Part NumberInlet / Outlet Connections (F.NPT) AWidth BCDEOperating Range (psig)

ECL502-22"2.25 57 mm3.5 89 mm.58 15 mm1 25 mm10-60 psig 0.7 - 4.1 barg

ECL502-10050 - 175 psig 3.4 - 12.1 barg

ECL502-123

ECL502-140

ECL502-175

ECL502-325150 - 350 psig 10.3 - 24.1 barg

Reliable Performance Under Extreme Conditions

The ECL502 Series is purpose-built for cryogenic applications, offering reliable operation in environments with very low temperatures. Its stainless steel construction and anti-corrosive properties ensure durability, while its bubble-tight shutoff and high flow efficiency maintain process integrity in critical settings such as LNG and air separation plants.

Flexible Installation and Maintenance Efficiency

Designed for installation in any position, the ECL502 economizer valve streamlines system integration. Inline maintenance is straightforward, reducing downtime and service costs. Available with various connection types, this valve adapts to existing infrastructure, providing unmatched versatility for distributors, exporters, manufacturers, and service providers.

FAQ's of ECL502 Series Cryogenic Economizer:

Q: How can the ECL502 Series Cryogenic Economizer Valve be installed in different orientations?

A: The ECL502 Series valve can be installed in any position, thanks to its versatile design. This feature allows for flexibility during installation, facilitating integration into diverse cryogenic gas systems without restriction to a specific orientation.Q: What processes and applications is the ECL502 valve suitable for?

A: This economizer valve is ideal for controlling pressure and flow in cryogenic gas systems, LNG facilities, air separation units, and similar operations. It efficiently handles cryogenic liquids and gases, supporting safe and reliable system performance.Q: When is it beneficial to use a valve with bubble-tight shutoff and high flow efficiency?

A: Utilizing the ECL502 Series for bubble-tight shutoff ensures complete isolation of media, which is crucial for safety and preventing leaks in cryogenic environments. Its high flow efficiency contributes to optimized energy usage and process accuracy during high-demand operations.Q: Where can the ECL502 Series be sourced and in what variants?

A: The ECL502 valve is available through distributors, exporters, importers, manufacturers, service providers, and suppliers across India. Offered in sizes from 1/2 to 2 inches (DN15-DN50) with various connection options such as butt weld, socket weld, and screwed ends.Q: What maintenance process is required for the ECL502 valve?

A: The valve is designed for easy inline maintenance, enabling quick servicing without the need to fully dismantle the system. This reduces downtime and enables efficient upkeep, ensuring continuous operation.Q: How is pressure regulated with the external pilot pneumatic control system?

A: Pressure is regulated by an external pilot pneumatic operator, which provides precise control over the valve's opening and closing. This system allows users to adjust settings according to process requirements while maintaining optimal safety and performance.Q: What benefits does the ASME/BS EN/ISO design standard provide for this economizer valve?

A: Adhering to international standards ensures consistent quality, safety, and compatibility. These certifications guarantee the valve performs reliably under global regulatory requirements, making it suitable for export and use in standardized industrial systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cryogenic Valves' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |