- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

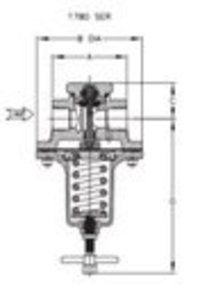

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

Heavy Duty Gas Line Regulator

20000.00 - 2000.00 INR/Piece

Product Details:

- Outlet Size 1/2 inch NPT Threaded Outlet

- Gas Type LPG, Natural Gas, Oxygen, Acetylene

- Material Brass and Stainless Steel

- Pressure Range 0.2 to 16 bar (Adjustable)

- Flow Rate Up to 40 m/hr

- Features Corrosion-resistant, Adjustable Pressure, Easy Installation, High Pressure Tolerance

- Usage & Applications Suitable for heavy-duty gas distribution in factories, workshops, and commercial kitchens

- Click to View more

X

Heavy Duty Gas Line Regulator Price And Quantity

- 20000.00 - 2000.00 INR/Piece

- 1 , , Piece

Heavy Duty Gas Line Regulator Product Specifications

- Corrosion-resistant, Adjustable Pressure, Easy Installation, High Pressure Tolerance

- Suitable for heavy-duty gas distribution in factories, workshops, and commercial kitchens

- 0.2 to 16 bar (Adjustable)

- Up to 40 m/hr

- Standard Size (Customizable as per Requirement)

- Brass and Stainless Steel

- Industrial Gas Supply Lines

- Precision Casting

- Heavy Duty Gas Line Regulator

- 1/2 inch NPT Threaded Outlet

- Approx. 1.5 kg

- Forged Brass Body with Stainless Steel Components

- LPG, Natural Gas, Oxygen, Acetylene

Heavy Duty Gas Line Regulator Trade Information

- As per the requirment Per Day

- 1 Week

Product Description

| Brand | REGO |

| Material | Brass |

| Usage/Application | Industrial |

| Color | Silvery White |

| Automation Grade | Manual |

Application

The 1780 Series Regulators are designed for final line pressure regulation on gas distribution systems. They are suitable for a variety of gases in medical or industrial applications. The 1780 Series Regulators have a balanced seat, are constructed with Oxygen compatible materials, and have the same valve design, brass body, and internal parts as the premium BR-1780 Series. Flow performance is equal to the BR-1780 Series.

Features

Maintains a steady downstream pressure across a range of inlet pressures commonly provided by a cryogenic bulk tank

Large seat and diaphragm areas provide high capacity with sensitive control of delivery pressure with low falloff

Two FNPT delivery pressure gauge ports are located (plugged) on each side of the valve

Two bonnet drain/vent holes to allow for different mounting orientation

T-handle adjusting screw

Maximum inlet pressure is 500 psig (34.5 barg)

Available in four delivery pressure ranges (A-D)

Temperature range: -40 F to +165 F. (-40C to +74C)

Cleaned for Oxygen service per CGA G-4.1

100% Factory Tested

Materials

Body ........................................................................ Forged Brass Bonnet ..................................................... Nickel Plated Aluminum Diaphragm.................................................. Nitrile with PTFE liner Springs and Fasteners .......................................... Stainless Steel

Other valve parts .................................................................. Brass

Seat Disc and O-Rings....................................... Viton is standard

For Carbon Dioxide or Nitrous Oxide service: Specify EPDM material for seat disc and O-rings, add E to end of part number.

Engineered for Industrial Performance

Precision casting and top-grade materials ensure the regulator withstands heavy-duty use and high pressures. Its robust construction, with rust-resistant electroplating, is ideal for challenging environments such as factories and commercial kitchens. Each unit comes with customizable sizes and box packaging, catering to specific requirements.

Versatile & Safe Gas Control

Designed for multiple gases-including LPG, natural gas, oxygen, and acetylene-the regulator offers adjustable pressure from 0.2 to 16 bar. The integrated over-pressure protection valve ensures secure operation and enhances workplace safety. Maintenance is straightforward, with easy servicing for continued reliable use.

FAQ's of Heavy Duty Gas Line Regulator:

Q: How is the Heavy Duty Gas Line Regulator installed?

A: The regulator can be easily mounted on a wall or panel using standard hardware. Simply connect the 3/4-inch NPT threaded inlet and the 1/2-inch NPT threaded outlet to the respective gas supply and distribution lines. Ensure secure fittings and check for leaks before use.Q: What types of gases can this regulator be used with?

A: This regulator is suitable for LPG, natural gas, oxygen, and acetylene. Its versatile design accommodates various applications in industrial settings, workshops, and commercial kitchens.Q: When should maintenance or servicing be carried out?

A: Routine inspection for leaks or wear should be done periodically, though the regulator is engineered for low maintenance. Servicing is simple, and guidance is typically provided in the product manual or by your supplier, with most components accessible for easy upkeep.Q: Where is this regulator commonly used?

A: The regulator is ideal for industrial gas supply lines found in factories, workshops, and commercial food preparation facilities. Its robust design also makes it suitable for export and broader industrial uses.Q: What benefits does the integrated over-pressure safety valve provide?

A: The integrated over-pressure protection ensures the regulator shuts off gas flow if pressures exceed safe limits, preventing potential hazards or damage to downstream equipment. This enhances overall operational safety and prolongs equipment life.Q: How does the electroplated finish improve durability?

A: The electroplated coating protects the brass and stainless steel components from rust and wear, even in humid or corrosive conditions, ensuring reliable performance and longer service life.Q: Can the regulator be customized for specific requirements?

A: Yes, while it comes in standard sizes, customization is available to suit unique installation needs or operational preferences. Please consult your distributor or supplier for details on available custom options.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LPG Valves ' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |