- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Angle Relief Valve, ASME AR4100 Series

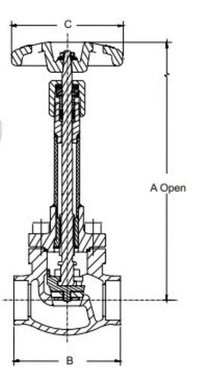

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

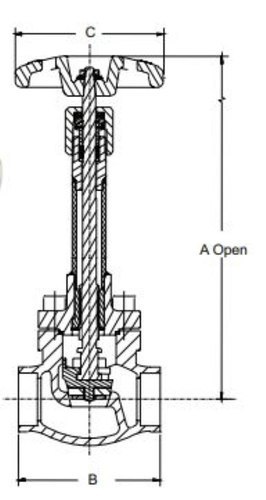

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

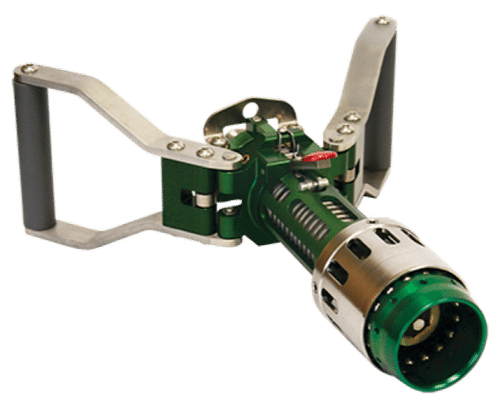

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

1600 INR/Piece

Product Details:

- Valve Type SKM Advantage Series Medium Stem

- Features Extended bonnet, blowout-proof stem, low emission packing, anti-static design, quarter-turn operation, panel mounting capability, clean and degreased for oxygen service

- Material Stainless Steel (CF8M, ASTM A351/CF8M)

- Control System Manual handwheel

- Connection Type Socket weld, butt weld, threaded or flanged ends

- Valve Size Available sizes: 1/2 to 2

- Structure Globe

- Click to View more

X

REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem Price And Quantity

- 10 Unit

- 1600 INR/Piece

REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem Product Specifications

- Socket weld, butt weld, threaded or flanged ends

- Manual handwheel

- DN15 to DN50 (1/2 to 2)

- Available sizes: 1/2 to 2

- Cryogenic Globe Valve

- Stainless steel

- Cryogenic liquids, industrial gases

- Cryogenic service for industrial gas, LNG, and liquid oxygen/nitrogen/argon service lines

- Manual

- PTFE seat, Metal-to-metal backup

- Up to 40 bar (580 psi)

- SKM Advantage Series Medium Stem

- -196C to +65C

- Globe

- Stainless Steel (CF8M, ASTM A351/CF8M)

- Extended bonnet, blowout-proof stem, low emission packing, anti-static design, quarter-turn operation, panel mounting capability, clean and degreased for oxygen service

REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

| Model Name/Number | SKM Advantage Series |

| Brand | REGO |

| Body Material | Stainless Steel |

| Usage/Application | Cryogenic Liquids |

ApplicationThe SK Advantage Series of Stainless Steel Globe Valves are designed for handling cryogenic liquids through trailer, bulk vessels and piping configurations. Ideal service medium includes Oxygen, Nitrogen, Krypton, Carbon Dioxide, Dinitrogen Monoxide, Carbon Oxide, Methane, Ethane, Ethylene, Argon and LNG . Our KoldSeal stem seal technology assures a tight seal preventing cryogen gas loss. The conical seat design allows exceptional flow, positive shut-off and less chance of debris accumulation in the flow path, all resulting in an overall longer service life. Maintenance on the packing and seat is quick and easy.

Features Soft Seat: PCTFE material which is the most widely specified cryogenic seat material in the industry

Construction: Bolted bonnet allows easy access to the valve internals for servicing

Stem Packing: Proven Kold-Seal technology, Live-loaded PTFE

Sizes: through 2

Connection: Socket Weld and Butt Weld

Service: Liquefied and vaporized atmospheric gases, LNG

Temperature Rating: -325F to +150F (-198C to +65C)

Pressure Rating: Cold, Non-Shock, 725 psig (50 barg) Class 300 (PN 50)

Cleaned for Oxygen service per CGA G-4.1

Application: Multiple stem lengths available for selected service

Packaging: Each valve is individually bagged and boxed to arrive in factory new condition until installation

Precision Built for Cryogenic Safety

Engineered specifically for cryogenic service, the SKM Advantage Series globe valves accommodate temperatures as low as -196C, making them ideal for use with industrial gases, LNG, and liquid oxygen, nitrogen, or argon. The extended bonnet and anti-static features not only promote safe operation but also enhance insulation, reducing vapor loss and ice formation risks during low-temperature transfers.

Superior Sealing Performance

With a dual-sealing system using PTFE seats and a metal-to-metal backup, as well as Class VI (bubble tight) leakage specification, these globe valves prevent even microscopic fluid leaks. Their electropolished surfaces ensure no particulate contamination-critical for oxygen service-while meeting stringent cleanliness and low emission standards, ensuring operational safety and purity.

Comprehensive Compliance and User-Friendly Design

Certified in accordance with ISO 21011, EN 1626, PED 2014/68/EU, ASME B16.34, and BS6364, these valves deliver peace of mind regarding quality and safety. Features like reduced operating torque, blowout-proof stem, low-emission graphite/PTFE packings, and the option of manual handwheel operation ensure easy, dependable use in various process settings.

FAQ's of REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem:

Q: How does the extended bonnet improve the valve's cryogenic performance?

A: The extended bonnet significantly enhances vapor insulation, reducing the risk of ice formation around the packing and handwheel. It keeps the stem seal area above the cold zone, ensuring smooth manual operation and minimizing the chance of leaks in cryogenic environments.Q: What are the primary benefits of the Class VI (bubble tight) leakage rating?

A: A Class VI leakage rating ensures that the valve provides a total shut-off with virtually zero leakage, even with cryogenic media. This ensures safety, prevents product loss, and maintains process integrity-vital for handling industrial gases and liquefied gases like LNG or liquid nitrogen.Q: When should a cryogenic globe valve with a metal-to-metal backup be selected?

A: Select a cryogenic globe valve with a metal-to-metal backup when additional sealing integrity and durability are required, especially during rapid temperature changes or in applications where PTFE seats might degrade over time. This backup system extends service life and guarantees reliable shut-off even if the primary seal is compromised.Q: How does the valve's design facilitate maintenance and safety?

A: The rising stem design with an external thread keeps stem threads away from direct contact with media, minimizing wear and facilitating inspection. Features like the blowout-proof stem and anti-static construction further enhance operational safety and ease of routine maintenance.Q: Where can these valves be installed, and what connection types are available?

A: These globe valves are suitable for installation in industrial gas pipelines, LNG facilities, and liquid oxygen/nitrogen/argon service lines. Connection options include socket weld, butt weld, threaded, or flanged ends, making them adaptable to a variety of piping systems and installation requirements.Q: What compliance and design standards do these valves meet?

A: SKM Advantage Series valves meet international standards, including ISO 21011, EN 1626, PED 2014/68/EU, ASME B16.34, and BS6364. They are also certified to be fire safe, which underscores their suitability for critical and hazardous service conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'LNG Cryogenic' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |