- Home Page

- Company Profile

-

Our Products

- LPG/LNG Level Gauge

- Servo Level Gauges with Local and Remote Readouts

- Rochester Level Gauges with Local and Remote Readout

- Dip Rod type LPG Level Gauge

- Radar Level Gauges with Local and Remote Readouts

- Rochester Level Transmitter

- DP Level Gauges

- Magnetic Level Gauges Dip Rod type LPG Level Gauge

- Radar Gauge

- Roto Gauges

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- REGO RG Series Cryogenic Pressure Builder or Regulator

- ECL502 Series Cryogenic Economizer

- Short Stem Cryogenic Valves

- Right Angle Relief Valves

- Cryogenic Valves

- Rego Relief Nozzle

- Rego MQD100 Series Cryogenic Valve

- REGO Heavy-Duty Gas Line Regulator 1780 Series

- Rego Extended Stem Retrofit Kits

- Interested in this product? Get Best Quote Rego ES8450 And TES8450 Series Extended Stem Valves, BK9450 And BK9470 Series Extended Bonnet Valves

- REGO Cryogenic Gas Relief Valves, Non-ASME 9400 Series

- REGO Cryogenic Gas Relief Valve , ASME PRV194630 And PRV29430 Series

- REGO Bulk Vessel Safety ASSE

- REGO 1784NG Gas Phase Regulator

- REGO Cryogenic 1/2" Pressure Builder PB Series

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- REGO Angle Relief Valve, ASME AR4100 Series

- REGO Stainless Steel Gate Valve for Cryogenic Service 110 Series

- REGO Stainless Steel Globe Valve for Cryogenic Service 210 Series

- REGO Stainless Steel Globe Valves for Cryogenic Service SKM Advantage Series Medium Stem

- Rego Lng Hoses Brass Connections CHB Series

- REGO CryoMac 50 GPM LNG Fueling Nozzle

- REGO Stainless Steel Globe Valves for Cryogenic Service SKL Advantage Series Long Stem

- REGO Stainless Steel Globe Valves for Cryogenic Service SKS Advantage Series Short Stem

- Rego LNG Male Fueling Receptacle MFR50 Series

- Rego LNG Check Valves NG Series

- Rego Cryogenic Fill Manifold CF, AFM, PFM And SFM Series

- Rego LNG Vent / Fill Breakaway VFL Series

- REGO Angle Relief Valve, ASME AR5100 Series

- REGO Strainer STR000002

- REGO Stainless Steel Swing Check Valve for Cryogenic Service 886 Series

- Rego LNG Female Vent Coupler FQD10 Series

- REGO Stainless Steel Angle Globe Valves for Cryogenic Service SKA Advantage Series

- LNG Hoses Stainless Steel Connections CHS Series

- Oxygen Cylinder Regulator

- LPG/LNG Level Gauge

- Services

- Clients

- Contact Us

- LPG/LNG Level Gauge

- Safety Relief Valves

- LPG Cylinders Valves

- Industrial Valves

- Pressure Transmitters

- Excess Flow Check Valves

- Coupling

- Level Gauges

- Portable LPG Tank Safety Fittings

- Auto LPG Dispensing Stations

- Pressure Relief Valves with Kalrez Seat

- Sight Flow Glass Indicators

- LNG Valves and Safety Fitting

- Cryogenic Valves

- LPG bullet Storage Tank

- Lot Valve Adapter

- LPG Valves

- Integrated Tank Management Systems

- Automobile Spare Part

- LNG Cryogenic

- Oxygen Cylinder Regulator

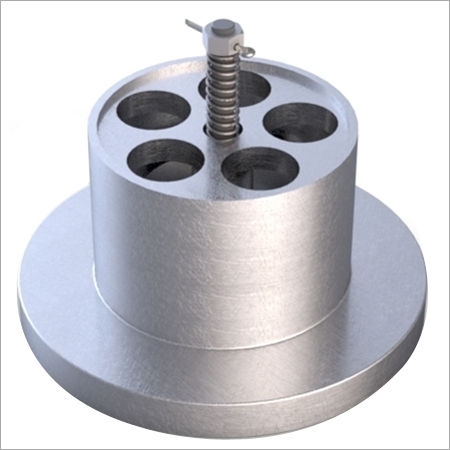

Excess Flow Valves

Product Details:

- Valve Size Available from 1/2 to 2

- Valve Type Safety Valve

- Features Quick Shutoff, Corrosion Resistant, High Sensitivity

- Material Brass / Stainless Steel

- Connection Type Threaded (BSP/NPT)

- Control System Direct Operated

- Sealing PTFE/Gasket

- Click to View more

X

Excess Flow Valves Price And Quantity

- 1 Piece

Excess Flow Valves Product Specifications

- Safety Valve

- -20C to 80C

- PTFE/Gasket

- 1/2 inch to 2 inch

- Available from 1/2 to 2

- Excess Flow Valve

- Gas, Liquid, Air

- Direct Operated

- Gas, Petroleum, Chemical Industries

- Threaded (BSP/NPT)

- Manual

- Quick Shutoff, Corrosion Resistant, High Sensitivity

- SS or Brass

- Ball or Piston Type

- Brass / Stainless Steel

- Max 300 psi

Excess Flow Valves Trade Information

- 100 Piece Per Day

- 1 Week

Product Description

The Excess Flow Valves manufactured and supplied by us are designed to stop when a sudden flow surge occurs. They automatically reset when pressure is restored. Also known as surge preventer, earthquake valve, shutdown valve, they are single line in which pressurized gas or liquid flows in either directions. Every valve has its own closing flow rate based on different conditions. Excess Flow Valves can be used for different types of fluids & processes like butane, nitrogen air, anhydrous ammonia, LP gas, water & various other. Moreover, they are available in a different variety of pressure materials, flange designs as well as end connections as per the customers requirements.

Product details

| Material | Brass |

| Size | 2inch |

| Country of Origin | Made in India |

| Finishing | Polished |

| Color | Golden |

High-Sensitivity Safety Solution

Engineered to react with instant shut-off in emergency situations, these excess flow valves maintain strict safety parameters for gas, liquid, and air systems. The corrosion-resistant materials and robust construction make them suitable for use in demanding environments, such as chemical plants or petroleum refineries, ensuring continuous protection and durability.

Versatile Applications and Customization

Designed for installation in both horizontal and vertical pipelines, these valves meet diverse industrial requirements. The shut-off differential is adaptable according to system needs, offering flexibility for specialized solutions. Their range of port sizes and connection types (BSP/NPT) ensures compatibility across various operational setups.

FAQs of Excess Flow Valves:

Q: How do excess flow valves provide safety in industrial applications?

A: Excess flow valves are essential for safety as they instantly shut off media flow when abnormal flow rates are detected, minimizing the risk of leaks or system failures. They are particularly effective for environments handling gases, liquids, or chemicals.Q: What is the recommended process for installing these valves?

A: Installation is straightforwardthese valves can be mounted either horizontally or vertically using the female threaded end connections. Always ensure the flow direction matches the uni-directional marking, and use appropriate PTFE or gaskets for sealing.Q: When should the shut-off differential be set or adjusted?

A: The shut-off differential should be configured during installation or system maintenance, tailored to the specific flow requirements of your application. This customization ensures optimal performance and safety according to process demands.Q: Where are these excess flow valves commonly used?

A: They are frequently installed in gas distribution pipelines, petroleum processing plants, chemical industries, and similar sectors across India where safety and rapid response to flow anomalies are crucial.Q: What are the benefits of using stainless steel for the spring and disc components?

A: Stainless steel offers excellent resilience, corrosion resistance, and longevity, which enhance the valves sensitivity and reliability even in harsh or corrosive environments.Q: How does the valve maintain a zero leakage rate?

A: The valves utilize precision sealing materials such as PTFE or gaskets, coupled with a well-engineered ball or piston design, ensuring a tight seal and preventing media leakage during operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Excess Flow Check Valves' category

|

SPECIAL STEEL COMPONENTS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |